Design, operation and advantages of a high-performance COMFLEX® grinding system developed by KHD Humboldt Wedag, Germany are examined. The system includes a roller press, a static V-separator and a dynamic SKS SEPMASTER separator. It is characterized by low power consum...

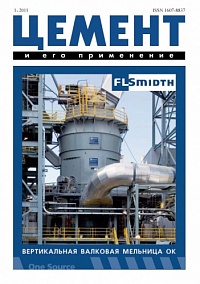

Now with an improved roller removal tool and a new grinding roller design, FLSmidth’s ATOX mill is set to help cement plants improve efficiency and keep downtime to a minimum.

The article deals with the incorporation of a power-engineering gas turbine unit in the line for drying and grinding of raw materials at PRUP Belorussky Cement Plant, which made it possible to generate electricity, utilize the heat of exhaust gases in the process, and p...

The article offers a technical and economic analysis of three different types of production and daylighting technology in the field, using as an example drilling and blasting operations, a mining milling combine and a Caterpillar 374DL hydraulic excavator with a set of ...

Claudius Peters company describes its new developments in silo technology based on systemic studies of the properties of materials, as well as on completed projects making use of these developments.

The need for inter-laboratory comparative tests (ICT) of cement is emphasized. The methodology and results of Russia’s first official ICT of cement held in 2008 are described. The results show that the quality of cement testing according to GOST 310.1 – GOST 310...

The report deals with the development of optimum parameters for the photocolorimetric method of monitoring the weight ratio of organic water-reducing admixtures based on polymethylene-naphthalene sulfonates, lignosulfonates, including when they are jointly present in co...

The article considers the experience of the factory laboratory at OAO Sukholozhsk-Cement in organization of a monitoring and control system at various stages of production: from the quarry to clinker grinding. Multi-purpose equipment, software for processing and analys...

The article discusses the production of low water demand binder (BLW) adding a liquid modifying agent in a centrifugal impact mill. The BLW thus obtained are very reactive, and possess 60% greater strength than the control samples.

The article deals with the issues of modeling the principal dispersion characteristics of powders depending on their specific surface area. The relationship of these parameters with the main technological properties of separated cements is demonstrated.