Since the beginning of 2021 Jura-Cement-Fabriken AG Switzerland has been using the newly launched PREMAS® 4.0 Predictive Maintenance Solution on an AUMUND Belt Bucket Elevator at its cement plant in Wildegg. PREMAS® 4.0 is an innovative digital monitoring system offered by AUMUND Fördertechnik GmbH, Rheinberg, for predictive maintenance.

Ramona Keller, Head of Maintenance at Jura-Cement-Fabriken AG, checking the IoT box which sends the collected data via a mobile connection to the PREMAS® Cloud. The PREMAS® Portal visualises and supplies all relevant data for complete online condition monitoring with secure access 24/7 for authorised users on any mobile or desktop device (photo AUMUND).

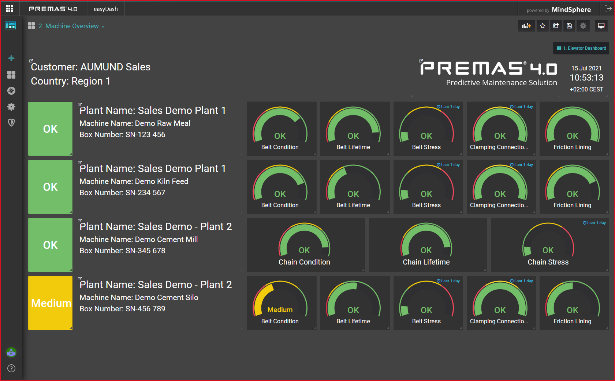

AUMUND IoT box and dashboard for real-time display of machine data (photos AUMUND)

Ramona Keller is Head of Maintenance at Jura-Cement-Fabriken AG, and after several months her experience with the Predictive Maintenance Solution has been positive. “We are convinced that predictive maintenance is the future. With PREMAS® 4.0 we can better plan our spare parts and maintenance, which has a positive effect on resources and costs. The PREMAS® Portal is easy to use and very clear. It allows us to recognise immediately when we need to act, no matter where we are or what time of day or night it is.”

PREMAS® 4.0 informs the maintenance department online, in real-time, about the condition of the machine, provides a prediction about the estimated lifespan of critical components, and facilitates proactive planning, timely action and prevention of possible problems.

Jura-Cement has been able to experience this since the beginning of 2021. Thanks to PREMAS® 4.0, wear and ageing of important machine components of the kiln-feed Belt Bucket Elevator at the Wildegg plant are flagged up at a very early stage. To make this possible PREMAS® 4.0 combines the latest sensor technologies with data collection and analysis. Jura-Cement has unlimited access to the condition of the AUMUND Bucket Elevator via the PREMAS® Portal, and is informed proactively by the abnormality recognition function as soon as any action needs to be taken. This can be triggered by various indicators such as lifespan and workload of the belt (which was installed in 2015), machinery performance over the past 30 days, and/or some of the most important variables such as belt lengthening, motor current, and temperatures measured at the Bucket Elevator head and boot.

PREMAS® 4.0 gives an overview of the most important indicators, the evaluation of which shows the condition of the conveying equipment:

• Machine KPIs: belt lifespan and condition, belt workload (the belt was installed in 2015), condition of the clamping connection, lifespan of the friction linings

• Machinery performance over the past 30 days

• Current measurements of the most important variables: belt lengthening, motor current, and temperatures at head and boot

• Detailed trend graphs

• Overview of the machines

The indicators allow the condition of the AUMUND Bucket Elevator to be monitored continuously.

The PREMAS® Portal visualises and supplies all relevant data for complete online condition monitoring with secure access 24/7 for authorised users on any mobile or desktop device. Thanks to the abnormality recognition function users are proactively informed as soon as any action needs to be taken.

At the beginning of 2020 Jura-Cement was the recipient of the first prototype of the PREMAS® 4.0 System. Test runs were carried out to collect and evaluate data to be visualised in the first version of the PREMAS® Portal. The finalised PREMAS® System was successfully installed in January 2021 and put into operation. During the entire test phase Jura-Cement actively provided feedback, making a significant contribution to successful development, and helping to bring the system to market.

About the AUMUND Group

The AUMUND Group is active worldwide. The conveying and storage specialists have special expertise at their disposal when dealing with bulk materials. With their high degree of individuality, both its technically sophisticated as well as innovative products have contributed to the AUMUND Group today being a market leader in many areas of conveying and storage technology. The manufacturing companies AUMUND Fördertechnik GmbH (Rheinberg, Germany), SCHADE Lagertechnik GmbH (Gelsenkirchen, Germany), SAMSON Materials Handling Ltd. (Ely, Great Britain), TILEMANN GmbH Chains & Components (Essen, Germany) as well as AUMUND Group Field Service GmbH and AUMUND Logistic GmbH (Rheinberg, Germany) are consolidated under the umbrella of the AUMUND Group. The global conveying and storage technology business is spearheaded through a total of 19 locations in Asia, Europe, North and South America and a total of five warehouses in Germany, USA, Brazil, Hong Kong and Saudi Arabia.