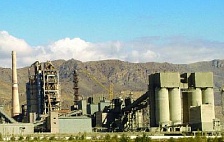

The Iskitim cement plant in Novosibirsk Region plans to upgrade filters on both smokestacks by 2024. A new electrostatic precipitator was installed on one of the kilns of the enterprise this year. According to the Director General of Iskitimcement Vladimir Skakun, the precipitator made it possible to reduce pollution by 160 times.

The plant is updating equipment to improve the environmental situation in the region.

“That’s the direction we’re planning to go for, and by 2024 we will change electric filters in both of our smokestacks entirely,” says Vladimir Skakun.

A bag filter produced by Scheuch (Austria) was installed on one of the cement kilns in the past year. In 2020, such filters should be installed on two more kilns. The cost of one filtering device is 160 million rubles. The plant has four cement kilns total.

“No more than three kilns at a time will operate in the next five years. Three is enough to meet our production capacity,” says the CEO.

The rest of the equipment on the plant is being repaired to improve the environmental situation. In 2019 the plant spent 12 million rubles for these purposes, and plans to spend 30 more in 2020.

The city of Iskitim is on the list of 22 most polluted Russian cities, according to the Ministry of Natural Resources of the Russian Federation. According to the ministry, the concentration of major pollutants in the city increases for the past five years.

Iskitimcement is one of the largest producers of cement in Siberia. The plant supplies products to Novosibirsk Region, Altai Territory, Khanty-Mansiysk and Yamalo-Nenets Autonomous Districts, Kemerovo, Omsk, Tomsk, Tyumen and Kurgan Regions, inclufding exports to Kazakhstan.The plant produced about 1 million tons of cement in 2019.

In December, Sibirsky Cement Holding [Sibcem] — owning a 49.9% stake in Iskitimcement — received an approval from Federal Antimonopoly Service to acquire a 100% of the stake.