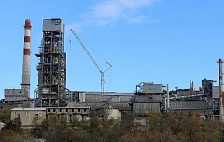

Smikom’s Serebryansky cement plant in the Ryazan Region finalized replaced overdue foreign production units with the Russian equipment local manufacturers as a part of the repair campaign. The substitution of imported equipment and components is a key policy of the plant’s management.

The holding seeks to reduce the dependence on exchange rate fluctuations, the company's representative said to ‘Cement and its Applications’.

During the 2020 repair campaign at the Serebryansky cement plant all foreign equipment and components were substituted with Russian analogues: an impeller for a gas-filling fan, a belt conveyor drive reducer, a limestone reclaimer drive hydraulic cylinder, centrifugal blowers for aerosheaths, clinker conveyor cells and rollers, limestone crusher hammers, rubber-fabric belts.

A number of substitute components are manufactured by Russian manufacturers according to the custom design schematics developed by the specialists of Serebryansky cement plant. These components include buckets of scraper conveyors of limestone and coal reclaimers, chains of clay and limestone reclaimers, armor lining of the grinding chamber and substandard chamber.

Smikom holding company initiated the import substitution process back in 2014. Preparation of Serebryansky cement plant for the 2020 season cost 287 million rubles.